Watertight Enclosure End Caps (6" Series) - End Cap - Aluminum - 5 x M10 Hole - 65m

Watertight Enclosure End Caps (6" Series) - End Cap - Aluminum - 5 x M10 Hole - 65m

Product Description

A variety of end cap and flange cap options for the 2″, 3″, 4″, 5″, 6″, and 8″ Series Watertight Enclosures allow you to customize your enclosure for your application. End caps require an O-ring sealing flange to be installed on the enclosure and flange caps have the O-ring sealing flange built-in so that one is not necessary.

The acrylic end caps and polycarbonate domes offer optically clear ports for cameras, lights, and other applications where optical clarity is important. They install to the O-ring sealing flange with included screws.

The flange caps are anodized aluminum and include the same features as the O-ring sealing flange including dual radial O-rings for reliable high-pressure sealing, a locking cord gland, and an anti-rotation feature. The flange caps are available with a solid blank end, which can be machined with custom hole patterns, as well as M10 threaded holes for our cable penetrators. The flange caps do not require any screws, eliminating the need for stainless steel near the enclosures and preventing galvanic corrosion.

The end caps and flange caps are available individually here, but you can configure a complete watertight enclosure from the watertight enclosure configuration page.

Technical Specifications

End Caps

| Series Diameter | Material | Hole Configuration | End Cap Screws | End Cap Screw Hole Circle (K) | Thickness ¹ (L) | Weight | Depth Rating ² | Part Number | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 mm (2") | Cast Acrylic | Blank (No holes) | M2x0.4-10 | Ø50.8 ± 0.1 mm | 6 mm [+0.63, -1.15] | 17 g | 500 m | BR-100094 | |||||||||||

| 75 mm (3") | Cast Acrylic | Blank (No holes) | M3x0.5-12 | Ø82.6 ± 0.1 mm | 9 mm [+0.75, -1.53] | 58 g | 400 m | BR-100949-998 | |||||||||||

| 100 mm (4") | Cast Acrylic | Blank (No holes) | M3x0.5-16 | Ø108.0 ± 0.1 mm | 12.7 mm [+0.05, -2.5] | 135 g | 300 m | BR-102993-998 | |||||||||||

| 130 mm (5") | Aluminum 7075-T6, type II anodized | Blank (No holes) | M3x0.5-12 | Ø133.0 ± 0.1 mm | 10 mm | 427 g | 1000 m | BR-102203-001 | |||||||||||

| 150 mm (6") | Cast Acrylic | Blank (No holes) | M3x0.5-16 | 158.7 ± 0.1 mm | 12.7 mm [+0.05, -2.5] | 331 g | 150 m | BR-102205-007 | |||||||||||

| 200 mm (8") | Cast Acrylic | Blank (No holes) | M3x0.5-16 | 209.1 ± 0.1 | 12.7 mm [+0.05, -2.5] | 564 g | 75 m | BR-102206-007 | |||||||||||

| Aluminum 6061-T6, type III anodized | Blank (No holes) | Note: flange integral to end cap, does not require separate flange. | 63 g | 1000 m | BR-100276-999 | ||||||||||||||

| 2x M10 Thru | 59 g | BR-100276-002 | |||||||||||||||||

| 4x M10x1.5 Threaded | 58 g | BR-100276-004 | |||||||||||||||||

| 1x M10 Thru 8x M06x1 Threaded | 60 g | BR-100276-009 | |||||||||||||||||

| Aluminum 6061-T6, type II anodized | Blank (No holes) | Ø82.6 ± 0.1 mm | 6 mm | 102 g | 1000 m | BR-100949-999 | |||||||||||||

| 4x M10 Thru | 6 mm | 97 g | BR-100949-004 | ||||||||||||||||

| 7x M10 Thru | 6 mm | 93 g | BR-100949-007 | ||||||||||||||||

| Aluminum 6061-T6, type II anodized | Blank (No holes) | M3x0.5-12 | 10 mm | 234 g | 1000 m | BR-102993-999 | |||||||||||||

| 5x M10 Thru | 10 mm | 223 g | BR-102993-005 | ||||||||||||||||

| 10x M10 Thru | 10 mm | 212 g | BR-102993-002 | ||||||||||||||||

| 7x M10 Thru 11x M10x1.5 Threaded | 10 mm | 196 g | BR-102993-003 | ||||||||||||||||

| 1x M10 Thru 4x M14 Thru | 10 mm | 215 g | BR-102993-004 | ||||||||||||||||

| 2x M10 Thru 8x M14 Thru | 10 mm | 195 g | BR-102993-006 | ||||||||||||||||

| 5x M10 Thru 2x M10x1.5 Threaded 8x M14x1.5 Threaded | 10 mm | 186 g | BR-102993-007 | ||||||||||||||||

| 5x M14 Thru 5x M10 Thru | 393 g | BR-102203-002 | |||||||||||||||||

| 10x M14 Thru 7x M10 Thru | 367 g | BR-102203-003 | |||||||||||||||||

| 11x M10 Thru 15x M10x1.5 Threaded | 369 g | BR-102203-004 | |||||||||||||||||

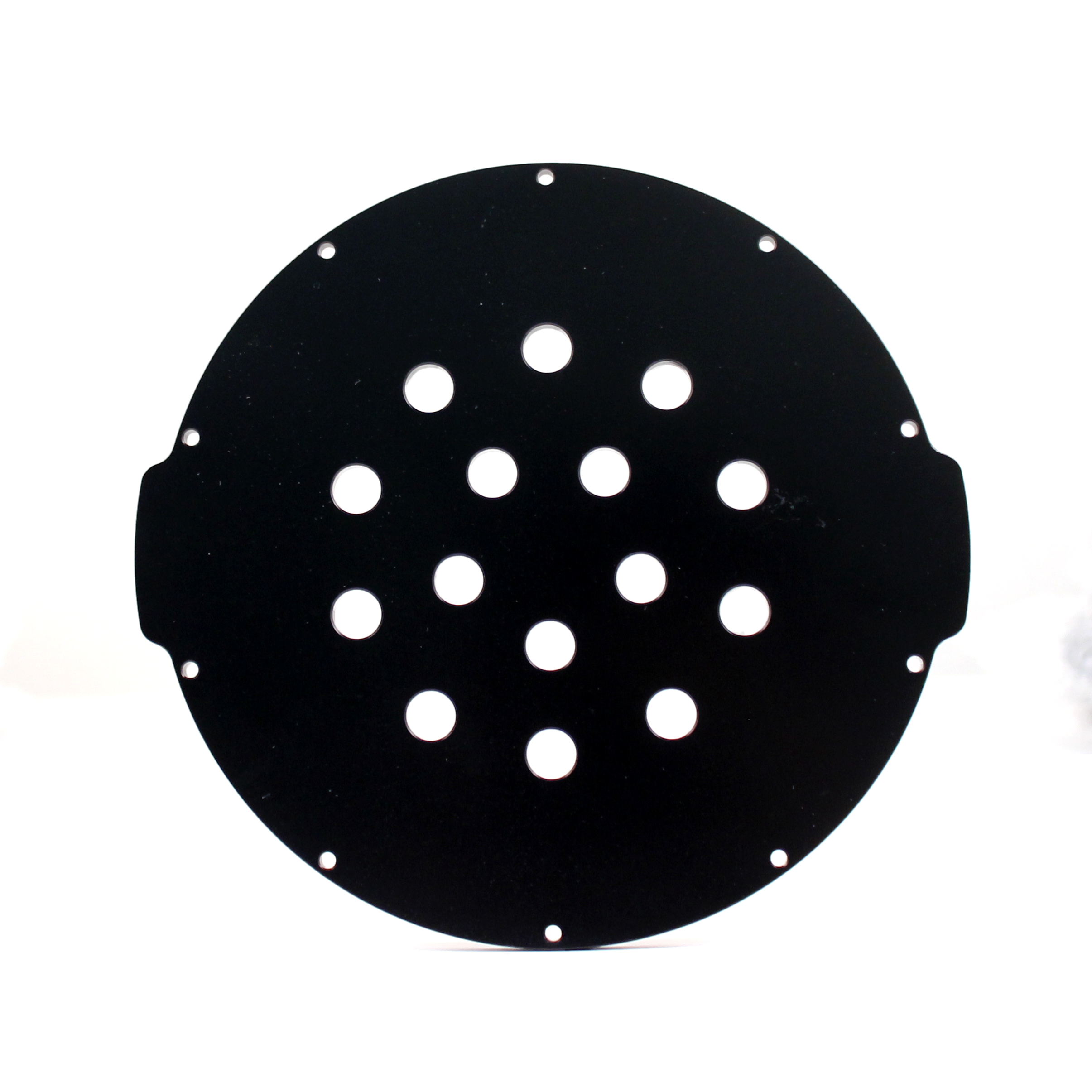

| Aluminum 6061-T6, type II anodized | Blank (No holes) | M3x0.5-12 | 6 mm | 359 g | 150 m | BR-102205-006 | |||||||||||||

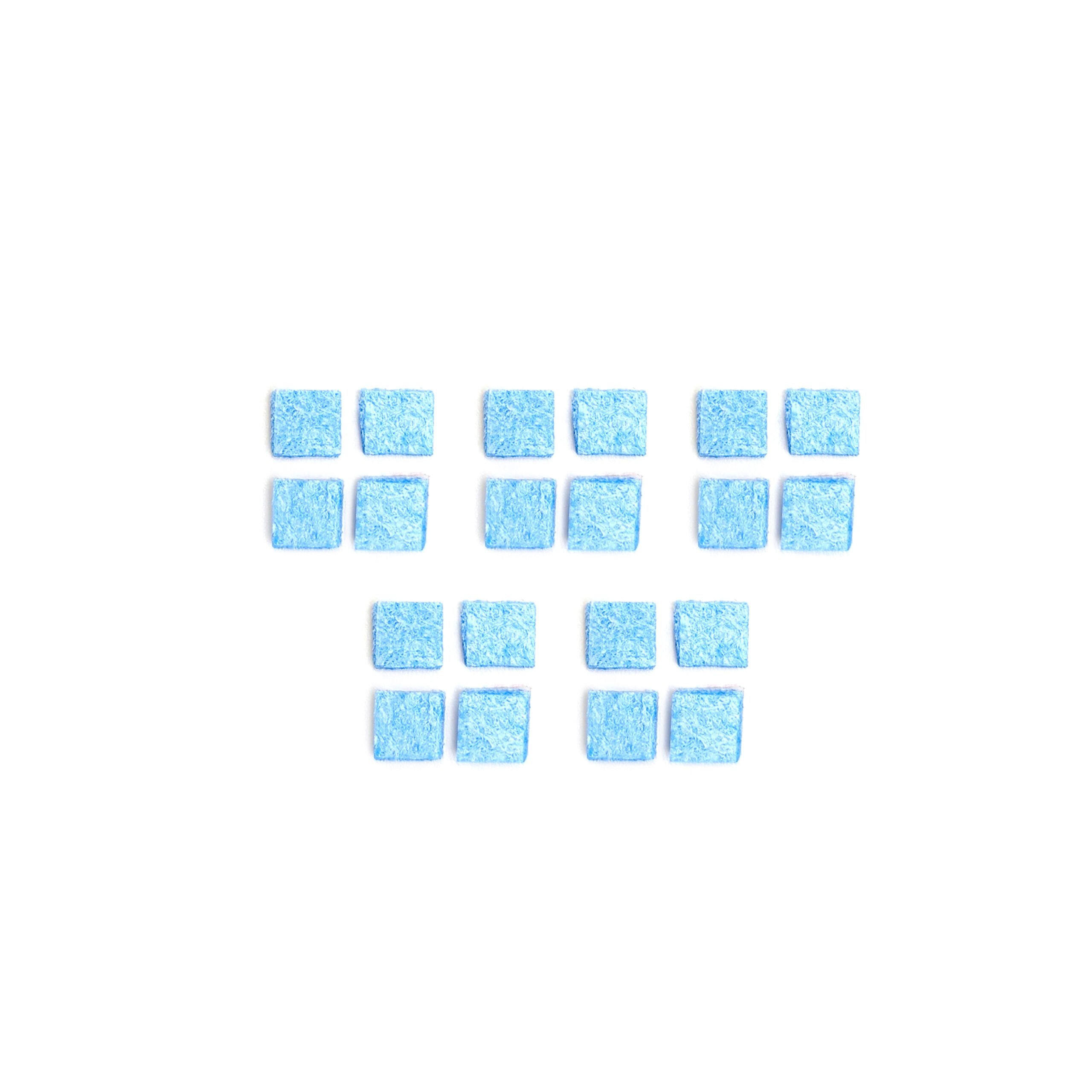

| 5x M10 Thru | 353 g | BR-102205-005 | |||||||||||||||||

| 15x M10 Thru | 339 g | BR-102205-004 | |||||||||||||||||

| Aluminum 7075-T6, type III anodized | Blank (No holes) | M3x0.5-12 | 158.7 ± 0.1 mm | 12 mm | 687 g | 1000 m | BR-102205-001 | ||||||||||||

| Aluminum 7075-T6, type II anodized | 5x M10 Thru 5x M14 Thru | 647 g | BR-102205-002 | ||||||||||||||||

| 16x M14 Thru 13x M10 Thru | 566 g | BR-102205-003 | |||||||||||||||||

| Aluminum 6061-T6, type II anodized | Blank (No holes) | M3x0.5-12 | 6 mm | 599 g | 75 m | BR-102206-006 | |||||||||||||

| 5x M10 Thru | 592 g | BR-102206-005 | |||||||||||||||||

| Aluminum 7075-T6, type II anodized | Blank (No holes) | M3x0.5-12 | 209.1 ± 0.1 | 16 mm | 1458 g | 1000 m | BR-102206-001 | ||||||||||||

| 5x M10 Thru 5x M14 Thru | 1370 g | BR-102206-002 | |||||||||||||||||

| 10x M10 Thru 10x M14 Thru | 1283 g | BR-102206-003 | |||||||||||||||||

| 16x M14 Thru 14x M10 Thru | 1191 g | BR-102206-004 | |||||||||||||||||

| ¹ Overall thickness tolerance ± 0.1 mm. ² The depth ratings for cast acrylic components are applicable only for short-term submersions lasting less than two weeks. For longer submersion, we suggest using aluminum components only. | |||||||||||||||||||

Domes

| Series Diameter | Material | Dome Internal Radius (M) | Dome Wall Thickness (N) | Screws | Weight | Depth Rating | Part Number |

|---|---|---|---|---|---|---|---|

| 50 mm (2") | Hardened polycarbonate dome, polycarbonate retaining ring | 18.0 ± 0.1 mm | 2.50 ± 0.10 mm | M2x0.4-10 | 15 g | 1000 m | BR-100859 |

| 75 mm (3") | 31.25 ± 0.10 mm | 3.1 ± 0.1 mm | M3x0.5-12 | 39 g | 750 m | BR-101059 | |

| 100 mm (4") | 43.5 ± 0.1 mm | 3.75 ± 0.10 mm | M3x0.5-12 | 81 g | 500 m | BR-100495 | |

| 130 mm (5") | 53.5 ± 0.05 | 7.00 ± 0.05 | M3x0.5-12 | 195 g | 600 m | BR-102597 |

FAQs

Didn't find your answer?

Don't hesitate to contact us.

You May Also Need

Watertight Enclosure End Caps, Domes, and Flange Caps - 100 mm (4") End Cap - Aluminum - 5 x M10 Hole - 950m

Related Products

Can't see what you need or have a query? Please just get in touch…